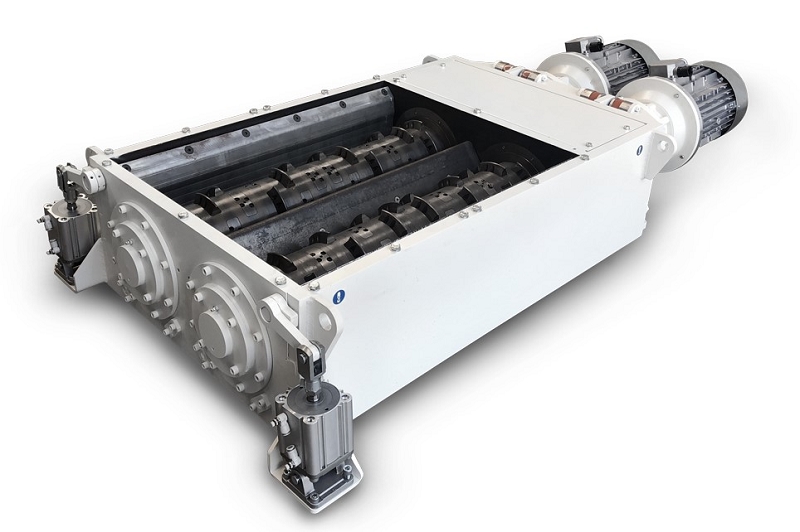

Horizontal shredder suitable for shredding long, coiled, very tough shavings, containing pieces.

It is ideal to be positioned under the machine tool evacuator but can be integrated into a treatment group.

The TRA1000 unit is a machine intended for shredding metal swarf to reduce its volume.

This machine is able to recognise the presence of metal parts (up to ∅=50 mm and L=80mm), present in the swarf to be processed, and to eject them autonomously.

The shredder is equipped with two slow rotating shafts moved by two geared motors of adequate power on which are mounted replaceable hooked knives, which, by crossing a counter-comb knife, create the cutting effect.

An interchangeable screen is installed under the shaft which, depending on the size of the openings, defines the size of the shredded chip and therefore the hourly output of the shredder. The efficiency of reducing the volume of the chips and the hourly output of the TRA1000 shredder can be evaluated with experimental tests on your chip at the headquarters of the company FAMA srl

EXPLORE

download TRABI1000 shredder product sheet [ pdf - 739 Kb ]

| HOURLY PRODUCTION |

| Q = 0,8 mc/h | Brass | Steel | Aluminium | Stainless steel | Copper |

| density [kg/dmc] | 0,45 ÷ 1 | 0,5 ÷ 1 | 0,15 ÷ 0,30 | 0,40 ÷ 1 | 0,25 ÷ 1 |

| Kg/h | 810 ÷ 1800 | 900 ÷ 1800 | 270 ÷ 540 | 720 ÷ 1800 | 450 ÷ 800 |

The data in kg/h is approximate and in any case depends on the density of the swarf, the shape, the oil content and the type of coolant. the density data considered are hypothetical, based on an experimental average of the data in our possession.