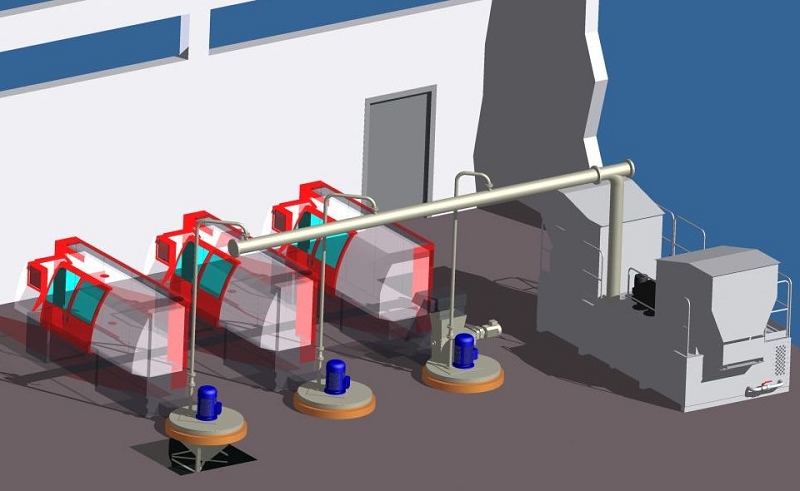

FAMA hydraulic systems are systems designed to collect and transport swarf and coolant directly from the machine tool continuously, automatically and without the need for the constant presence of an operator.

FAMA hydraulic systems are systems designed to collect and centralize swarf and coolant.

The goal is to collect and transport chips and coolant directly from the machine tool continuously, automatically and without the need for the constant presence of an operator. It is a versatile and non-invasive system, easily extensible and modifiable over time.

Among the main advantages of hydraulic systems, it is worth mentioning the elimination of all problems related to the movement of oil and swarf.

The hydraulic transport system must then be completed with a lubricant filtration and replenishment system.

The construction of civil works may be necessary.

EXPLORE

download Hydraulic swarf transport system product sheet [ pdf - 1254 Kb ]

| HOURLY PRODUCTION |

| Q = 0,8 mc/h | Brass | Steel | Aluminium | Stainless steel | Copper | Cast Iron |

| density [kg/dmc] | 1,5 | 1,3 | 0,8 | 1,1 | 1,00 | 1,4 |

| Kg/h | 1200 | 1050 | 640 | 900 | 800 | 1150 |

THE DATA IN kg/h IS APPROXIMATE AND IN ANY CASE DEPENDS ON THE DENSITY OF THE SWARF, THE SHAPE, THE OIL CONTENT AND THE TYPE OF COOLANT. THE DENSITY DATA CONSIDERED ARE HYPOTHETICAL, BASED ON AN EXPERIMENTAL AVERAGE OF THE DATA IN OUR POSSESSION.