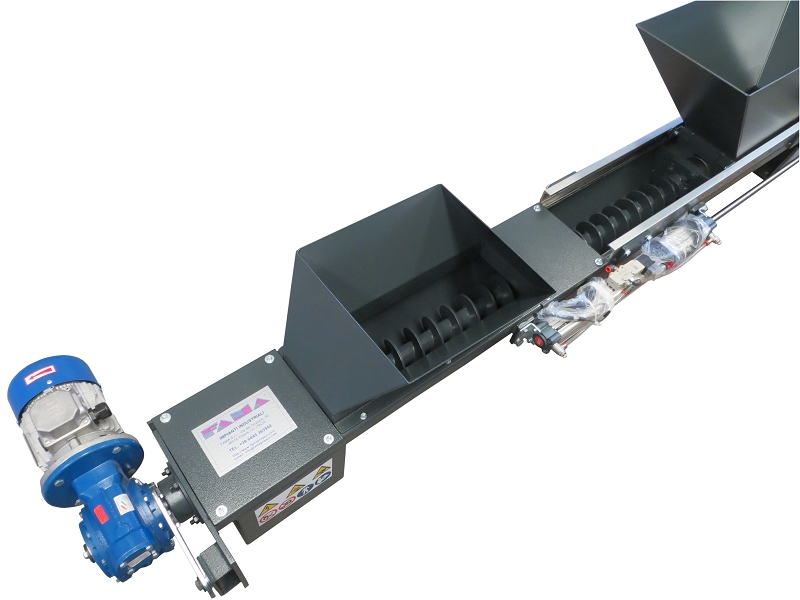

The screw conveyor can transport short chips horizontally, obliquely and vertically limiting the overall dimensions. It is usually employed to move metal chips from one device to another or on discharge of a treatment device for filling a storage container. If the transported chip contains coolant, the conveyor is equipped with a collection tank.

The screw conveyor uses a worm screw to transport short swarf from one device to another or to convey it to a storage site (container).

The screw is inserted into a channel or into a sheet metal pipe measuring 30/10, reinforced and supported, and is driven by a 0.35 kW geared motor. The channel can be made with wear-resistant elements for the parts in greatest contact with the swarf, if this is particularly abrasive.

It can be horizontal or inclined or have bidirectional motion. It can also be equipped with a swarf collection hopper (optional) or serve as a dosing unit for a collection tank. It is often equipped with inspection doors. To increase the quantity of swarf transported, the conveyor can be equipped with a double screw.

EXPLORE

download Screw conveyor product sheet [ pdf - 1221 Kb ]

| HOURLY PRODUCTION |

| Q = 0,8 mc/h | Brass | Steel | Aluminium | Stainless steel | Copper | Cast Iron |

| density [kg/dmc] | 1,5 | 1,3 | 0,8 | 1,1 | 1,00 | 1,4 |

| Kg/h | To be sized according to requirements | |||||

THE DATA IN kg/h IS APPROXIMATE AND IN ANY CASE DEPENDS ON THE DENSITY OF THE SWARF, THE SHAPE, THE OIL CONTENT AND THE TYPE OF COOLANT. THE DENSITY DATA CONSIDERED ARE HYPOTHETICAL, BASED ON AN EXPERIMENTAL AVERAGE OF THE DATA IN OUR POSSESSION.